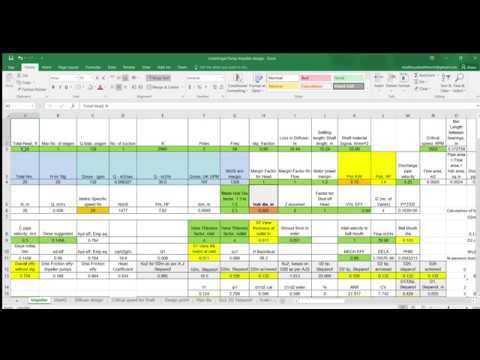

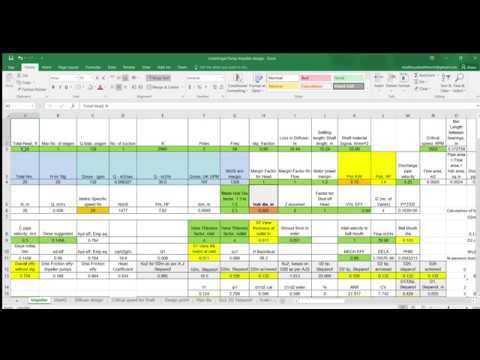

Centrifugal fan design calculations xls.

Centrifugal fan impeller design calculation xls.

The design of the centrifugal pump impeller is not a universally standardized one.

The impeller is mounted on a rotating shaft and enclosed in a stationary casing.

Every firm depends on its designer s experience expertise and technical intuition to design a good impeller.

Fan affinity laws.

The double discharge volute casing is a structural constraint and is maintained for its shape.

A method is presented for redesigning a centrifugal impeller and its inlet duct.

The fact that the impeller flow physics has not been understood fully has led the designers to fall back on.

Centrifugal fan design odologies dust collection research er centrifugal pump impeller design excel you free impeller and pump design software miscellaneous caeses forum.

In line tubular centrifugal.

All of which have individual benefits volume pressure speed power efficiency etc but all of them will shift gases at the same rate based upon the input power.

Casings are generally of two types.

Differences such as efficiency or flow rate occur in the type of fan due to particular design advantages that favour one characteristic over another.

Impeller axial centrifugala sirocco etc.

Note that the affinity laws for pumps are not identical with fans.

Geometrically similarity by change in impeller diameter.

During this process stage velocity pressure and discharge at different stages are calculated.

Spread sheet for the total head of fans and duct and fitting pressure drop.

Change in wheel speed revolutions per minute rpm and or.

Axial centrifugal fan blade design whilst these calculation options are primarily for the performance characteristics of an impeller via blade configuration they also offer the performance effects of an external casing.

The affinity laws for centrifugal pumps and fans are used to express the influence on volume capacity head pressure and or power consumption due to.

Centrifugal fan types are.

The generic calculation option therefore defines the performance characteristics of the fan using calculation results from axial or centrifugal.

The impeller design and the shape of the casing determine how liquid is accelerated though the pump.

Download free mep calculation excel sheets autocad drawings and training courses for hvac firefighting plumbing and electrical systems design.

The highest speed of the centrifugal fans.

Given the high performance of the baseline impeller the redesign adopted a high.

Radial blade or radial tip.

Download fan static head excel sheet calculator.

The highest efficiency of all of the centrifugal fans.

Some general types of the centrifugal pumps are as below.

Centrifugal fan design methodologies studies on radial tipped centrifugal fan 112 after inlet duct.

Whats people lookup in this blog.

Energy balance is established at fan inlet intermediate stage of impeller and outlet stage of volute scroll casing.

Centrifugal fan impeller design calculation xls.

There are a number of fan types.